Jere Northrop and Andrius Kulikauskas lead this Math 4 Wisdom study group

More Links

Ecotechnology

Welcome: This page will describe how technologies that are derived in concert with the Language of Wisdom may represent easily understandable illustrations of how the Language of Wisdom can function in real world hands on applications that will teach us to think ecologically. For this to be successful it is essential that we actually get involved in doing these ecotechnologies. Just reading about it, or watching videos, will not lead to a complete understanding of how these ecotechnologies work.

The first example will describe the TimberFish Technology, an ecotechnology that can produce clean seafood from sustainably harvested woodlots and forests and food production and processing wastes. See https://www.e-c-o.net/wiki/Econet/TimberFishTechnologies

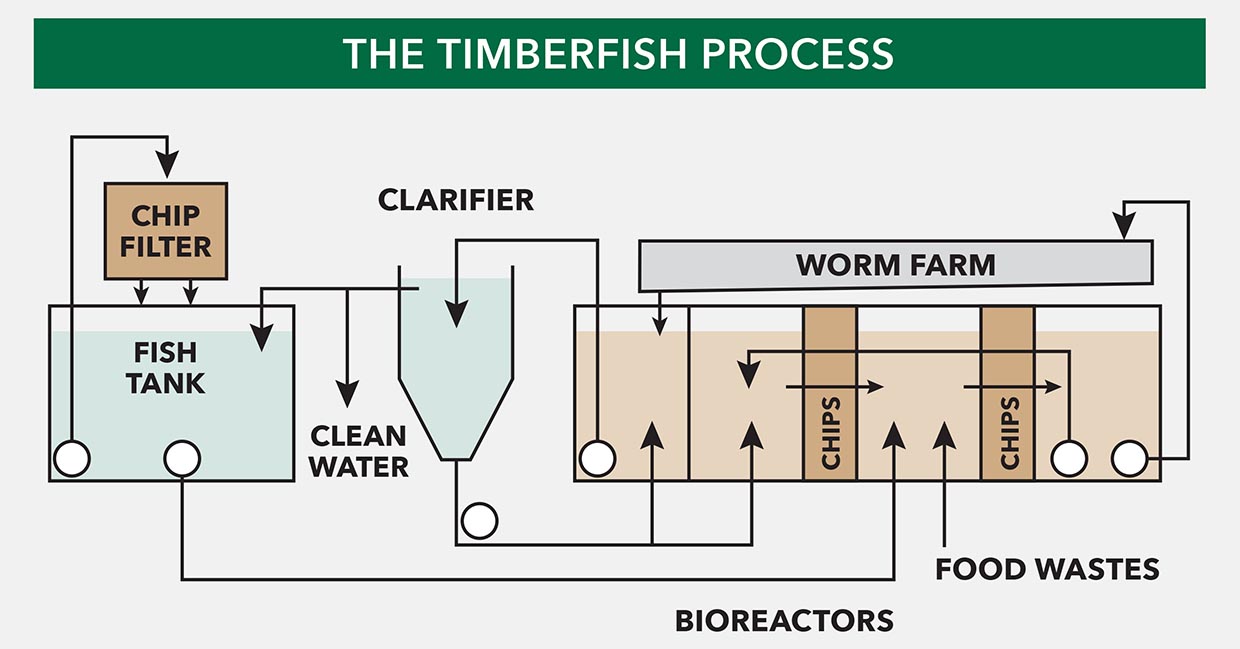

Here is a description of the Process:

The TimberFish Technology (TFT) combines elements from Recirculating Aquaculture Systems, Integrated Multi-Trophic Aquaculture, and Biological Municipal Wastewater Treatment. The resulting technology has been implemented in a complex and diversified ecosystem production facility that raises fish and other seafood utilizing plant material harvested from non- agricultural land and production residuals from the food and beverage industries as sole material inputs.

The TFT mimics the natural food-chain of fish and macro-invertebrates. It combines water purification and underutilized biomass to produce salable seafood and biofuels. The process is local, sustainable, environmentally friendly, removes solid and soluble pollutants from water; creates contaminant-free seafood; is not dependent on chemical use; and generates enhanced biofuels. TFT is economically attractive, providing a commercial driver for the global proliferation of environmental best practices including reforestation and deforestation avoidance.

The process comprises a series of interconnected internal recycle flows and sub environments that contain a large variety of organisms ranging from microbes, to invertebrates, and fish. It works by combining plant material with nutrients contained in by-product waste streams. The microbes are grown in this mixture and then become food for the invertebrates that are also resident within the system. The structure of the system is such that it is easy to provide these invertebrates to the product fish or other seafood that also reside within the system for their consumption.

The TFT system is designed to contain an extremely large variety of microorganisms and many different species of invertebrates. All of these can reside in various physical sub environments ranging from suspended floc structures and single cell aggregates to fixed film layers that will reside on the matrices comprising wood chips, grain hulls, and other grain and fruit non fermented residues.

A general schematic of the process is as follows.

TimberFish Technologies (TFT)

The TFT system has a four language interconnected structure that will be discussed in detail in the Epistemology of Ecotechnology sub page. The four languages represent a four level multitrophic design comprising;

- An atomic biochemical level using the language of free energy and maximum entropy,

- A microbial cellular level using a genetic algorithm language,

- An animal level using a neural network language, and,

- A human level using our natural, constructed, and computer languages.

These are related – interrelated by a metaphorical quaternion representation of the Golidlocks Maximum Entropy Principle (GMEP). See pages 94 – 95 in Chapter 7 of The Relational Symmetry Paradigm (RSP). This formulation has been developed concurrently with the physical manifestation and implementation of the TFT ecotechnology.

A description of this ecotechnology was also included in The RSP. See pages 108 – 127. Some of that material is contained in the following discussion. It was originally included in the RSP to illustrate how the constant interplay of theoretical and applied language can generate the new ecotechnologies that are essential for us to survive as a species and as a planetary ecosystem. Our current thinking is that this ecotechnology must be implemented on a global business level to achieve this objective.

We are currently reactivating TimberFish LLC. With a focus on an initial project to;

Develop Sustainability Programs for colleges and universities.

These programs would provide a hands on educational experience that would show how an ecotechnology such as TimberFish can not only demonstrate, but actually implement sustainability at the local level. The program would comprise a series of demonstration units, one of which could involve the installation of a mobile TFT unit at the college or university. Students could then operate the unit to convert plant material from nearby forests and woodlots and clean nutrient sources such as food wastes from cafeterias into fish. Here is a photo of such a demo unit.